Products

High-strength alloy applications

Aluminium is one of the most important representatives for metallic lightweight materials. It is extremely easy to process, and can be recycled infinitely. The differences in aluminium alloys mainly arise from their formability, strength, weather resistance and weldability.

Aluminium alloys contain numerous alloying elements that influence the material’s properties. The main alloying elements used include silicon, magnesium, manganese, copper and zinc, among others. e.g. they increase strength or improve corrosion resistance using a process known as solid solution strengthening. Furthermore, special alloying elements such as bismuth or lead are used to improve chip breaking during milling, drilling and turning, or silver to prevent sparking.

Most importantly, our customers expect the following from our aluminium alloys:

Large load capacity

High strength

Quality

Reliability

Primary aluminium is only used at EGA Leichtmetall very selectively and in small quantities. We mainly use secondary aluminium and alloy it with various elements such as zinc, magnesium, copper, manganese or tin. Elements such as beryllium or vanadium are also used for special applications.

EGA Leichtmetall currently produces more than 125 different aluminium alloys

For many of our customers, simply complying with the chemical composition in accordance with the standards is not enough. Therefore, we offer to design or further restrict the analysis specifications specifically based on their processing requirements and quality demands for the end product. Here you will find a selection of alloys conforming to standards and the restrictions we can implement with regard to the alloying elements. The product data sheets also contain the possible dimensions that can be supplied as well as empirical values for physical and technological properties.

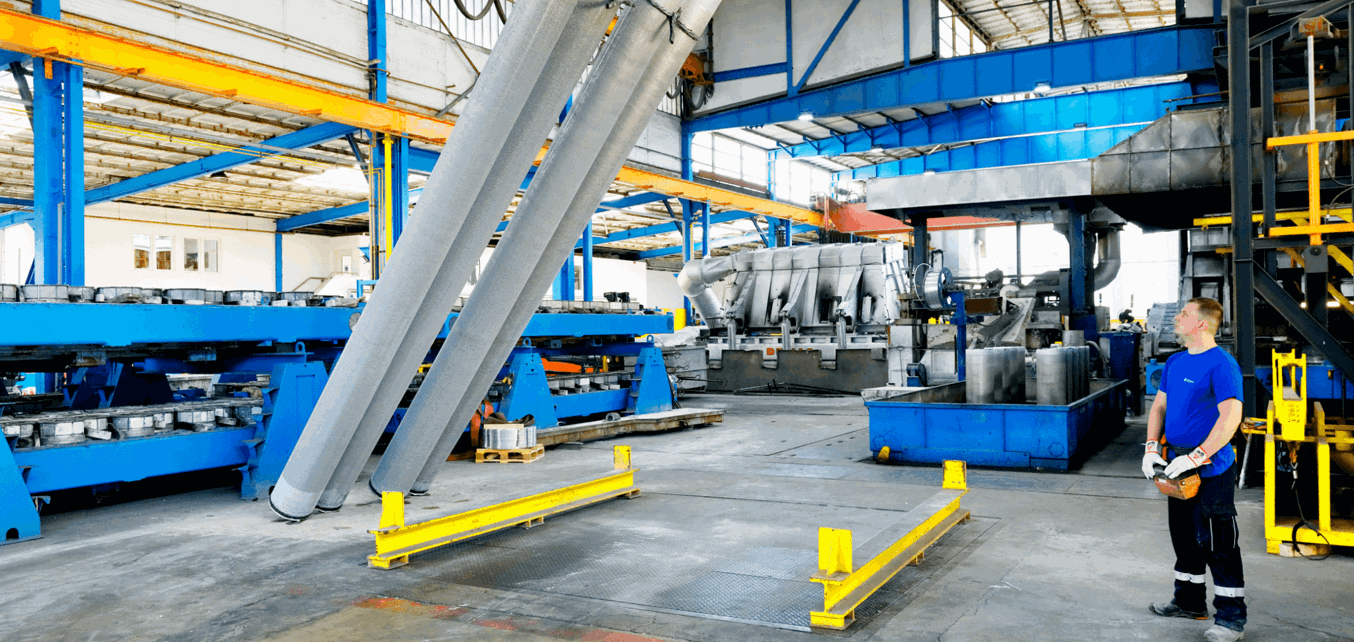

Aluminium alloys melting and processing

At Leichtmetall, we work with up to 99 per cent secondary aluminium, depending on the alloy. Secondary aluminium is aluminium scrap which is intensively tested and prepared at Leichtmetall before processing. We subject all incoming goods to a detailed chemical analysis. This gives us full control over the raw materials we use at all times.

We melt secondary aluminium and additional metals such as copper, magnesium, silicon or zinc in two tiltable 50-tonne channel induction furnaces, which are 100 per cent powered by renewable electricity.

Continuous casting: after various cleaning steps, we cast all alloys into billets using the level vertical continuous casting process under constant quality control.

Result: round billets with alloy-specific cold dimensions of 158 mm up 1,080 mm in diameter and a length of up to 7,000 mm. Hard alloys from Leichtmetall. More than just high-strength aluminium.

Our wrought alloys are mainly processed using forming methods - such as extrusion, forging or rolling. Many different products are made from them, such as structural components for aircraft, profiles or hydraulic tubes.

High-strength aluminium alloy applications

High-strength aluminium alloys distinguish themselves thanks to their high strength, excellent load-bearing capacity, extreme flexibility and low weight. In automotive production, the share of aluminium components has increased by around 300 per cent in the last 20 years. For example, two-thirds of a Formula 1 racing car is made of aluminium – despite fierce competition from carbon or titanium. Here, above all, 7000-series alloys are breaking into classic steel domains and replacing lightweight B-pillars in cars, for example.

Our quality controls

- Raw materials analysis

- Chemical analysis before casting

- Nine-fold sampling of each batch to determine its chemical composition

- Hydrogen measurement

- Metallographic analysis

Wrought aluminium alloys at EGA Leichtmetall

Not all aluminium is created equal. Wrought aluminium alloys are usually designated by a four-digit number system established by the Aluminium Association instead of their material number. Here, the first digit indicates the main alloying element and consequently, the alloy group. The remaining digits are more or less counting numbers, assigned chronologically or following existing alloys.

Aluminium is extremely easy to process. With optimal properties for technical requirements, aluminium is very easy to form and is particularly resistant to corrosion, has high strength, a large load capacity while offering extreme flexibility and a low weight.

At Leichtmetall, we currently manufacture more than 125 different alloys to standard – and above all – to your specific customer requirements.

Aluminium alloys and their properties

Different alloying elements are used to achieve the desired material properties, depending on the intended application.

Application:

- Aircraft manufacturing

- Defence technology

- Rail cars

Application:

- Automotive industry

- Heat sinks

- Mechanical engineering

Application:

- Shipbuilding

- Chemical industry

Application:

- Automotive industry

- Construction

- Mechanical engineering

Application:

- Defence technology

- Structural components in aerospace engineering

Typical applications for components made of high-strength aluminium:

- Orthopedics

- Seamless tubes and pipes

- Wire rod rings

- Rolled circular blanks

- Floor crossbeams

- Pistons and piston rods

- Control arms and tie rods

- Wheels for tracked vehicles

- Longitudinal stiffening of aircraft wings

- Turned parts, precision engineering

- Body and fuselage structures

- Gas cylinders and pressurized cylinders

- Cable housing

- Door closing systems

- Pipes for cooling systems and drills for oil and gas extraction

- ABS housing

- Aircraft seats

Overview of our main alloys